Production of anchor bolts and foundation tie rods on design

The term tie rods specifically identify the foundation tie rods or foundation bolts. They are called in many ways, more or less appropriate, but their purpose is always the same: being the bond between the base material and the element to be fixed.

When sizing the foundation bolt it’s essential to take into consideration the element to be fixed, the base material and the anchor bolt. The latter are subject to combined shear and traction actions which they must resist.

Officina Bonacina produces foundation tie rods and anchor bolts, made on the customer’s design or developed according to their needs for civil and industrial works,building and carpentry. The products can be made in all types of construction steel, round for concrete, tempered and tempered steel and stainless steel; with diameters from 6 to 100 mm and lengths up to 6 metres.

The end of the foundation bolt which is to be embedded in the casting can be hot or cold bent, stamped or supplied with a welded plate.

Anchor bolts equipped with plates and accessory bolts

Officina Bonacina offers its products equipped with nuts, washers and threaded sleeves or carpentry elements such as pipes, plates and templates for installation. Accessory hardware may be assembled prior to shipment to ensure proper assembly, especially in the case of hot dip galvanizing.

Plates and accessory bolts can be welded in the company, according to customer specifications, for immediate installation. Thermal or surface treatments are carried out on request, according to the customer’s needs.

Our offer of anchor bolts is in the territory of Lecco, city and province, in the neighbouring provinces of Como, Bergamo, Monza e Brianza, Milan and throughout Italy.

How to choose an anchoring system

The correct choice of an anchor must take into account the type of base material in which it will be inserted (concrete, cracked or non-cracked, plasterboard, hollow brick, etc.).

It will also be advisable to keep in mind the laying geometry, i.e. the thickness of the base material, the distance between the anchors and the distance from the edges. For example, the size of the anchor must be chosen on the basis of the depth of installation in order not to risk that the system loses effectiveness.

Another indispensable aspect for choosing the right anchor consists in the careful evaluation of the size and type of load. In most cases, an anchorage is subjected to combined static shear and traction loads, and will therefore have a design strength greater than the applied load.

Finally, the choice of anchoring must take place according to the environmental conditions, taking into account the characteristics of resistance with reference to corrosion and fire. The anchoring must in fact be evaluated on the basis of the level of aggressiveness of the environment since it can undergo a corrosive attack due to humidity, condensation or the presence of chlorides.

The anchor will therefore have completely different characteristics if it is to be installed in interior environments devoid of humidity or in highly corrosive environments such as road tunnels or covered swimming pools. In the first case the galvanizing alone will be sufficient to protect the anchor, while in the second case the use of stainless steel products will be necessary.

In places defined as being at greatest risk in the event of a fire, the anchors must resist the action of the fire for a time such as to guarantee the evacuation of the people involved. The choice must be made by comparing the design resistance with that which the element must possess after this period of time.

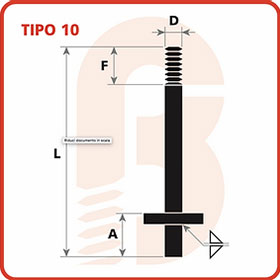

There are many types of anchor bolts. The following are some of those that can be made by Officina Bonacina:

- L-shaped anchor bolts: their name is linked to the shape of the tie rods, which are bent at 90° at one end.

- Hammer head bolts: these are hammer head bolts with a bulb composed of chamfered plates. These plates are welded directly to the bar or, alternatively, fixed to it with the aid of nuts, assembled plates or washers, with nuts and plates welded to the bolt or, alternatively, by hot heading the bar.

- Dovetail bolts: also known as “split”, they have a bar engraved and opened in two at one end, giving life to a particular V shape. These bolts are regulated by the provisions included in DIN 529 c.

The products are made using only materials of European production and provided with 3.1 certificate (according to EN 10204:2005) and CE marking (according to EN 1090).

Get in touch with the experts of Officina Bonacina for a quote or dedicated advice.